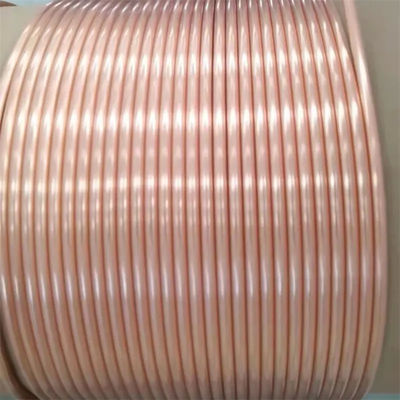

99.9% Copper Pancake Coil Pancake Coil Copper Tube

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Copper Pipe | Type | Copper Tube |

|---|---|---|---|

| Grade | Brass / Copper | Cu (Min) | 99.9% |

| Shape | Round | Application | Air Condition Or Refrigerator/Water Tube/Water Heater/O |

| Highlight | 99.9% copper pancake coil,Refrigerator copper pancake coil,Pancake Coil Copper Tube |

||

Composition of copper pipe

Copper pipes are typically made of copper that is at least 99.9% pure. The most commonly used type of copper for pipes is referred to as "Type L" copper, which is a high-quality copper alloy that contains a small amount of lead to make it easier to bend and shape.

Type L copper contains approximately 95% copper and 5% zinc. Other elements such as lead, arsenic, and phosphorus may also be present in small amounts.

Copper pipes may also be made from other copper alloys such as Type K copper, which has a higher copper content (approximately 99.9%) and is often used in high-pressure applications, or Type M copper, which has a thinner wall and is used for low-pressure applications.

Copper pipes may also be coated with a thin layer of solder to enhance their durability and resistance to corrosion.

Overall, copper pipes are made of high-quality copper alloys that are designed to withstand the rigors of plumbing applications while providing excellent thermal conductivity, corrosion resistance, and ease of installation.

Application of copper pipe

Copper pipes are commonly used for plumbing systems in residential, commercial, and industrial buildings. Some common applications of copper pipes include:

Water supply: Copper pipes are commonly used for cold and hot water supply systems due to their durability, corrosion resistance, and ability to handle high pressure.

Heating systems: Copper pipes are often used for heating systems such as radiators, boilers, and underfloor heating due to their ability to withstand high temperatures.

Air conditioning and refrigeration: Copper pipes are commonly used in air conditioning and refrigeration systems due to their high heat transfer properties.

Gas supply: Copper pipes are often used for gas supply systems due to their ability to handle high pressure and resistance to corrosion.

Solar panels: Copper pipes are used in solar panels to transfer heat from the collector to the storage tank.

Fire sprinkler systems: Copper pipes are commonly used in fire sprinkler systems due to their ability to withstand high pressure and resistance to corrosion.

Medical gas supply: Copper pipes are used for medical gas supply systems in hospitals due to their cleanliness, durability, and resistance to corrosion.

Overall, copper pipes are a versatile and reliable plumbing material that offer a range of advantages for various applications in different industries.

| Product Name | Copper Pipe/Copper Tube | |

| Material | C1220,C12000,C10200,T1,T2,T3,TP2,TU1,TU2,TU3,H62,H65,H70,etc | |

| Standard | GB/T17791-2007,GB/T1527-2006, GB/T18033-2007, YS/T450-2002 ASTM B280,ASTM B68,ASTM B75,ASTM B88 EN12735,AS1571,JIS H3300,etc. | |

| Model Number | 3/16'',1/4 ",3/8",1/2", 5/8" ,3/4" 7/ 8'' ,1'' copper tube | |

| OD | 3/16'',1/4 ",3/8",1/2", 5/8" ,3/4" 7/ 8'' ,1'' or Customized | |

| Ultimate Strength | 370MPa | |

| Elongation (≥ %) | 40% | |

| Length | 15m/roll, 50m/roll or customized | |

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard. | |

| Temper | O-H112; T3-T8; T351-T851 | |

| Surface | Mill finish, polished, anodizing, brushing, sand blasting, powder coating,etc | |

| Application | Widely used inair conditioners,refrigerators,electric,solar water heater, polished pipe an be used in decorative,such as stairrail. | |

| Samples | Can provide samples | |

| Certification | ISO9001,CE.ect. | |

| MOQ | 200 kg, If the purchase quantity is less than our MOQ, can be customized according to your requirements. | |

| Payment | T/T, D/A, D/P, L/C, Western Union, Money Gram or according to customer requirements. | |

| Delivery time | Usually within 7 days, the time depends on the number of products. | |

| Package | 1. Pancake coil copper tube:individually sealed by plastic bag,and packed by carton or box of 3-20 rolls2. LWC(plain) copper tube:withunit weight 100kgs more and packed individually by reel,6-7 coils packed by one pallet 3. Straight copper tube:Each piece end capped,bundled with plastic bag,then put in the wooden box or container 4. The packaging can be customized according to customer requirements. | |

| Advantages | 1. Reasonable price with excellent quality 2. Abundant stock and prompt delivery 3. Rich supply and export experience, sincere service | |

![]()

![]()

![]()

![]()

Quality Control

![]()

Production Processing

![]()

Packing & Delivery

![]()

![]()

FAQ

A:Yes, we are manufacturers. We have our own factory and our own company. I believe we will be the most suitable supplier for you.

A: Sure, we welcome you to visit our factory , check our production lines and know more about our strength and quality.

A: Yes, we have ISO, BV, MTC, certifications and our own quality control laboratory.Third party testing services are also available

A: Yes, we have designated sea freight and railway freight forwarders with decades of experiences and we get the best price with earlist vessel and professional service.

A: Generally it is 7days if we have the exact goods in our stock. If not, it will take around 15-20 days to get goods ready for delivery.

A: We are glad to provide free samples to you, but we do not offer the freight.

A: We provide after-sale service and offer 100% guarantee on our products.